Published 2016

Leaky tach cable solution

by RayB(itsa68)

I have a new old stock transmission repair kit which lists the speedometer pinion oil seal as 32709-14600. The oil seal inside the box is exact same one as measured for the tachometer pinion and has same manufacturer name and number. Nismo has them listed for $2.

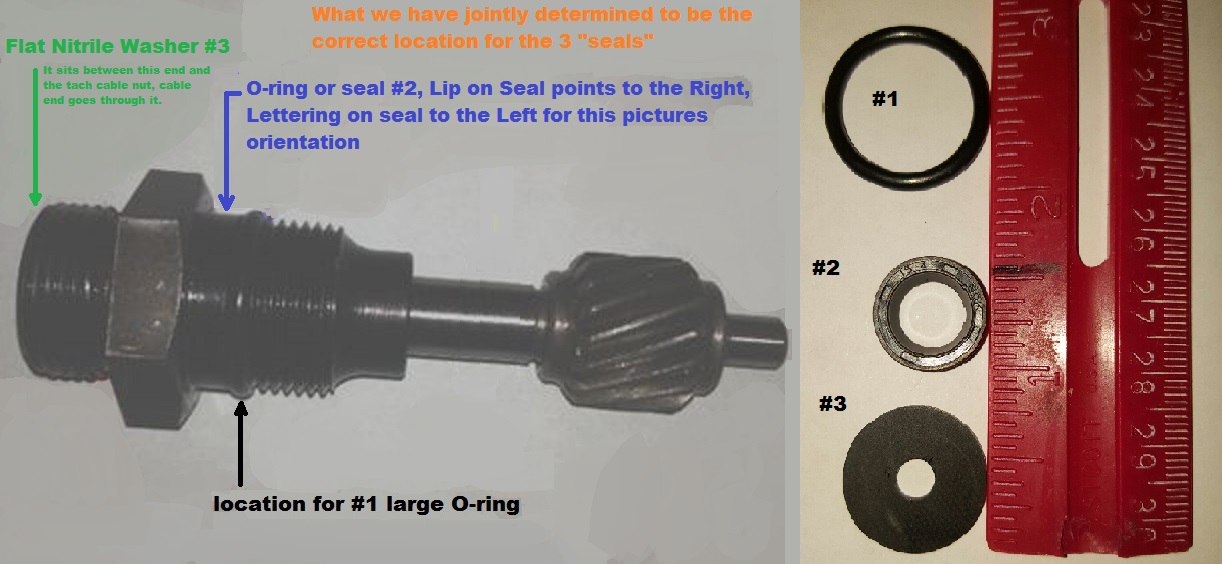

The 7/8" diameter o-ring which fits over the threads of the pinion assembly ,which screws into the casting, is 32710-14600. This joint never seems to leak ,so I would not bother getting a spare one.

You could probably also get an over the counter alternate oil seal from your local bearing supply house by supplying them with the inside diameter of the pinion sleeve, outside diameter of pinion shaft and the thickness of old oil seal. Also bring your old one with you as an example.

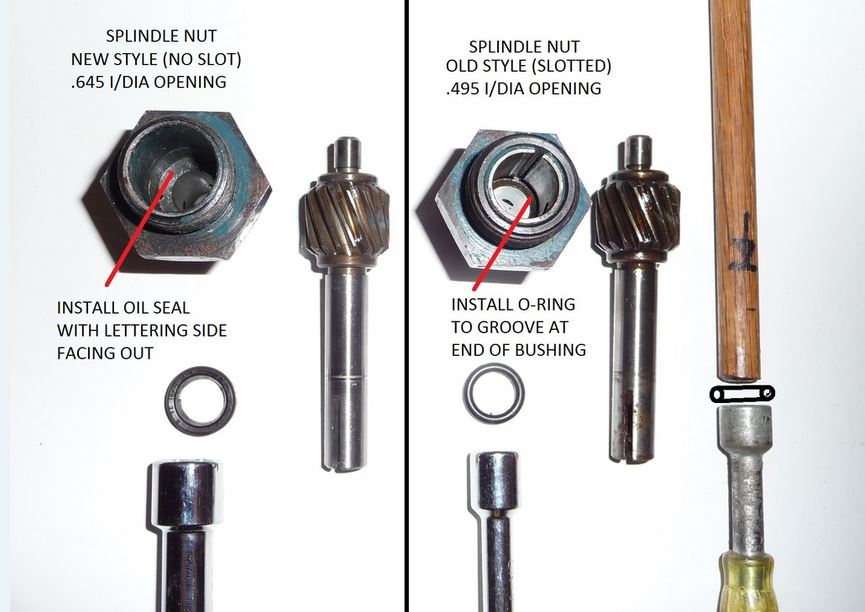

There are actually two styles regarding the spindle nut. The New style has the oil seal installed inside the spindle housing nut to seal the spindle shaft. The older style spindle housing nuts used an o-ring that fits inside a groove. The new style has the oil seal pushed in to the .645 diameter opening to the very bottom.

See attached pic to see the difference between what we are calling "new style" and "old style".

So, how it is done and are there are any parts that might come flying out. Depends on whether you have the old style-slotted .495 diameter opening or the newer style with no slot .645 diameter opening.

No loose parts should fall out. Unscrew the pinion housing nut and the pinion should stay in the distributor base with its shaft sticking out. On the pinion housing nut you removed, notice that there is an "o-ring" on the threads. This o-ring rarely leaks. Look inside the counter-bored hole on the cable side of the pinion housing nut and you will see the small black oil seal at the very bottom. The flat side of the oil seal is facing towards you at the cable attachment end of the housing nut (the grooved side faces towards pinion shaft).

Remove oil seal using dentists pick (or seal hook),using caution as not to scratch inside the housing nut bore. (The seal is pressed in pretty tight to the bore, so it might take some tongue to get it out.)If you get some minor scratching on the inside you can give it a quick light hone with some 400-600 emery paper and wash of any grit residue.

Put some motor oil/wheel bearing grease on new oil seal and install with grooved side facing towards bottom of the pinion housing nut counter-bore. Use a piece of hardwood dowel (with a squared off end and is same size as the outside diameter of the seal) and push the oil seal into the bottom of the housing nut counter-bore until "seal seats square against the bottom of the hole".

For the older style, here is a trick to get the o-ring into the groove behind the slotted bushing. Get 3/8 inch diameter wooden dowel and insert from opposite of the nut end. Insert the dowel to the depth which is flush to the inside end of the slotted bushing. Place o-ring in nut end and use a socket or nut driver same diameter as the inside diameter of the slotted bushing. Push the o-ring to stop against the end of the dowel and trap between the nut driver to flatten out the o-ring. When trapped move back and forth a tiny bit and the o-ring should seat itself into the groove. O-ring size should be 39/64 inch outside diameter and 7/64 inch thick.

Put some oil/grease on the housing nut o-ring and pinion shaft and re-install pinion housing nut to distributor base. Re-attach tachometer cable...and you done and no more leaks.

Here is a side shot of the pinion assembly. This shows the exterior seal placement (which many have gotten wrong) and shows the assembly all together and the length of the pinion nut.

Seal #3 above is not discussed much. This is the third seal that goes on the cable end which is actually more like a washer. People ask about a replacement for it and the washer is sold in a 3 piece kit with the other two seals or alone by several of the vendors. It is a nitrile washer type seal.

The speedometer cable oil seal at the transmission end (under the 90 degree speedometer adapter) is done in same manner, but if I recall correctly, the pinion shaft wants to drop out when the pinion sleeve is removed."

Thanks to Ray and numerous others for the invaluable information and pictures.