311 Economy Rotessiere

OK, over a year after I made mention of my economy body rotessiere, and Steve asking for a write up, I have finally got the body on it and took some pic's. Steve, you can move this if you think it should be located somewhere else. Here goes-

First off, I purchased a couple of basic engine stands from Harbor Freight (a local bargain tool supply house) for $40.00 each. As shipped, these are set up to hold an engine back at an angle, which would not work if you are trying to spin 2 of them at the same time. the solution I used was to level the pivot and then measure the distance from the ground to the bottom of the stand. I then went to the local hardware store to get some swivel casters as close as possible to the dimension needed. In my case, I found the exact size needed, but if you don't, spacers could easily be made. You will want to get the type that has a 1/2" threaded stud so you can drill the bottom of the stand and attach the casters to the stand with a hex nut. Make sure to get a good quality model that will withstand the load of the body.

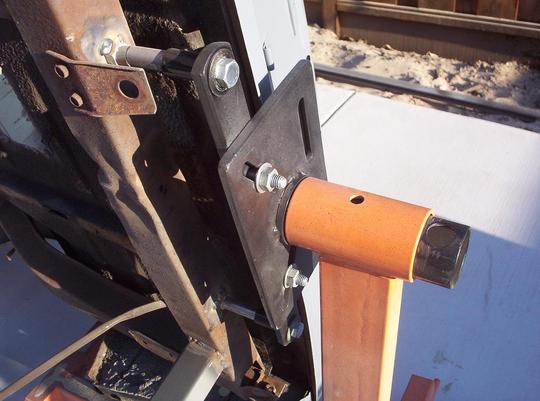

Next step is to attach the engine stand to the body. In my case, I had a old bent frame that I used to mount the body to. I cut the engine crossmember and x frame out to lessen the weight. This can also be done with some 2" tube steel or large angle iron with some fabrication and welding needed. If you make your own, be sure to either make it full length or if you do a front and back section, make sure to brace the door opening. In my case, with the frame I'm using, I simply welded a pair of 1/2" hex nuts to the frame and mounted the adapter to the nuts welded to the frame with 1/2" bolts. The rear did require some spacers to get it away from the body.

The spacing will vary depending on the adapter but simply measure to the center of your body mount and split the difference of the adapter center to center dimension and go 1/2 that dimension from the centerline of the body mount. When you set the adapter, try to get the center of the pivot as close as you can to the centerline of the body. This will allow you to rotate the body with little effort. (mine will turn with 1 hand with no effort) Adjust the angle of the arms on the adapter to give you the clearance required to completely twirl the body. If I were to move mine around alot, I would tie the 2 engine stands together with some sort of steel. For my situation, the frame hold the stands together well enough for the small amount of moving I do.

This same setup was used on the frame when I stripped it and painted it. Made it a piece of cake! One other thing I made for it is some wheels for the frame so when it is not on the rotesserie, I can have a portable body dolly to move it around on. This can be seen in the pic's as the 2" tube steel that is welded to the frame that has the wheel mounts welded on. The wheels are removed to allow the assembly to rotate-minor miscalculation.

I hope this helps some of you out in making you own inexpensive rotesserie. If you have any questions, I would be glad to help out where I can.

Thanks for sharing Mark.