Published 2009

Rear Wheel Bearings

So you have some strange noises coming from the rear of your car. This is one of those things you do not want to put off. A scraping sound usually indicates a bad wheel bearing or it could just be the metal backing shield rubbing the drum. A whining sound could indicate low differential fluid which has put undo wear on the gears. Checking the level of fluid in the rear end should be done periodically on a regular basis. Use 90 WT gear oil. Wheel bearing replacement is much easier than replacing axles and rear end gears. A little preventive maintenance will go a long ways and eliminates most problems before they occur.

The first thing to do is to break the wheel lugs loose while the car is still on the ground. Next jack the rear end of the car up and place jack stands under the frame for secure support. Remove the tires and rims, disconnect the emergency brake and the brake line at the wheel cylinder. Grab a container to catch the brake fluid. Remove the brake drum, then remove the brake shoes. There are four bolts holding the axle in place. Remove them and with any luck the axle will slide out with a some gentle tapping of a rubber mallet. I have always been lucky but if you come upon a stubborn one, you may have to use a slide hammer to remove the axle. A slide hammer is relatively inexpensive to rent if you do need one. There are some small metal shims in between the axle flange and the rear end housing. Make sure you pay special attention to how they came off. They are there to put a preload on the bearings. Do not leave them out or mix them up as this may cause premature bearing failure.

Now we can get a good look at the bearing. If it is not obviously worn, try turning it by hand and feel for any resistance or wear. I just helped one of the club members and his drivers side bearing was flaking out chunks of metal. No doubt that his noise was coming from this bad bearing. Do not scrimp and do just one side either. Take a look at both sides--and if one side is bad I would replace both. They are not that expensive.

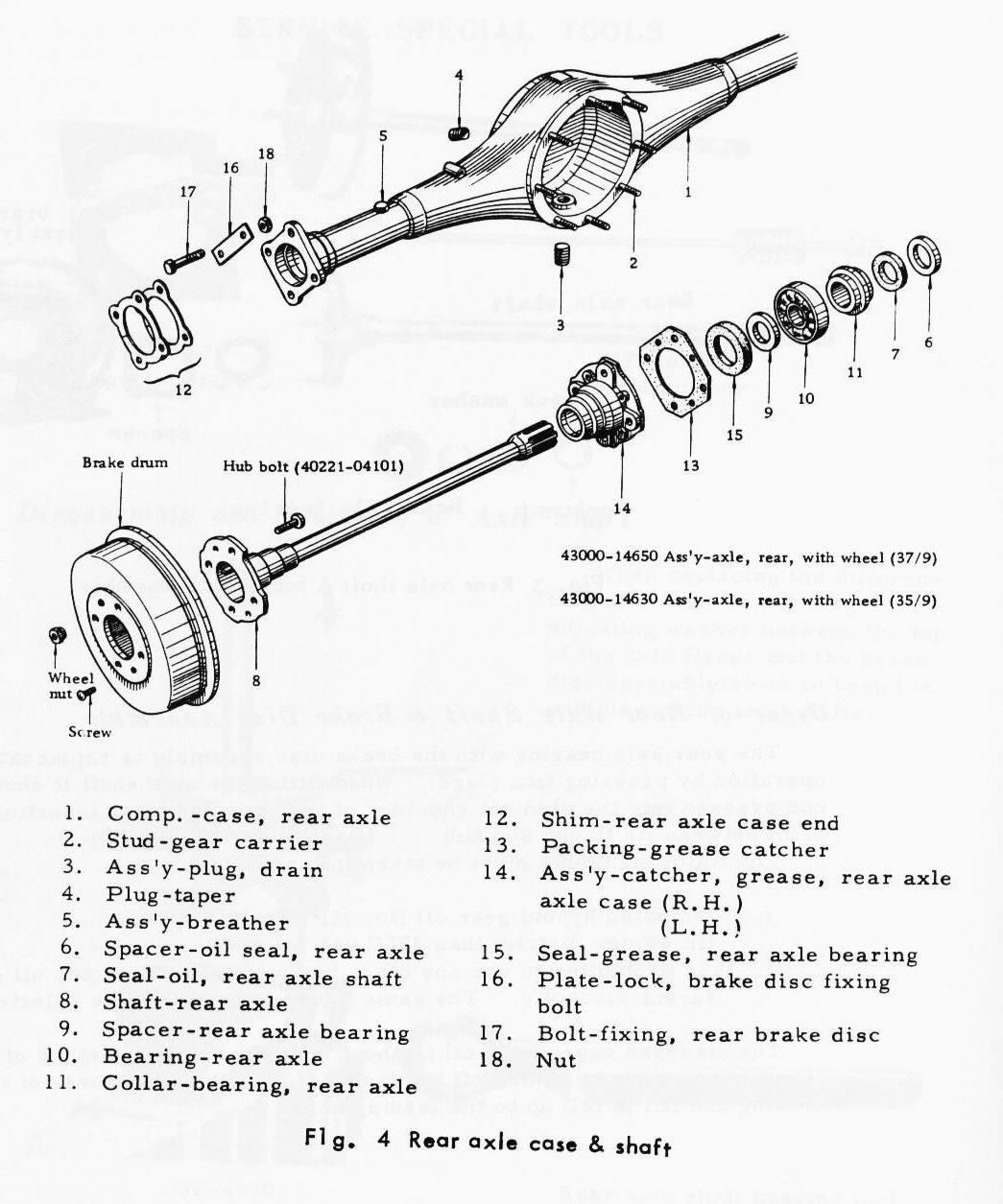

As you can see in the illustration below there is a collar that keeps the bearing in place on the axle. This collar needs to be removed in order to replace the worn components. You can have it pressed off or you can cut the collar off with a cutoff tool. Be careful not to damage the axle itself. My friend just had the machine shop press the old ones off, put the new parts on and press the new collar on. If the collar just slides off or on you need new axles. Not very likely to happen but..... My friend had both axles done for $50.00. Pretty cheap for California. Your price will vary according to location.

Here are the Nissan part numbers for the parts you will need to order plus some of the miscellaneous stuff for a complete axle refurbish.

- 2 each axle bearing-43215-08000

- 2 each axle collar-43084-10600

- 2 each outside catcher seal-43234-18401

- 2 each inner seals-38212-04104

- 1 each pinion seal-38189-P0101

- 1 each differential gasket-38320-B3002

- ^^6 each 5/16" x 24 x 1-1/2" grade 8 bolts with locking nuts

- ^2 each 5/16" x 24 x 1-1/4" grade 8 bolts with locking nuts

Check to make sure the new bearings are the same thickness as the old ones. If they are not the same you will have to adjust the shims accordingly. Here is the part number for axle shims--P/N 43036-04100. I have no idea what thickness the shim is. Originally there were three thicknesses available from Nissan.

Pack the new bearings with a good automotive grade grease of your choice. Do not mix greases if you are just repacking the bearings. Spend a little time cleaning them up and repack them with new grease.

Once that is done we can begin reassembly. Slide the axle back into the housing ensuring the shims are in place. Using the four bolts and lock nuts reattach the axle to the rear end housing. Reconnect the emergency brake and brake line to the wheel cylinder. Reinstall the brakes shoes along with their springs. Put hub back on and mount the tire and rim. Bleed your brakes as per brake bleeding and you are ready to roll.