311 Clutch Issues

Published 2007

The clutch system is a hydraulic affair driven by a clutch master and slave cylinder, fork, throw-out bearing, clutch pressure plate, clutch disk, and a pilot bushing. Unfortunately when a clutch has problems there is no simple remedy and almost always results in an engine/tranny pulling party. Things to check before you pull the engine:

- Air in the clutch master

- Incorrect clutch adjustment at the slave

- Worn components on the pedal and clutch rod yoke

Air in the clutch master will cause you problems. Bleed the system until all air bubbles have been purged. I highly recommend using a Motive Power bleeder to accomplish this task. A word of note on the Motive Power Bleeder--the adapter does not fit worth a darn on the single or dual brake master or the clutch master. I could not get it to seal because of the close proximity to the firewall. I ended up cutting a half inch off of the adapter so I can butt it up against the firewall. Now, it works just fine.

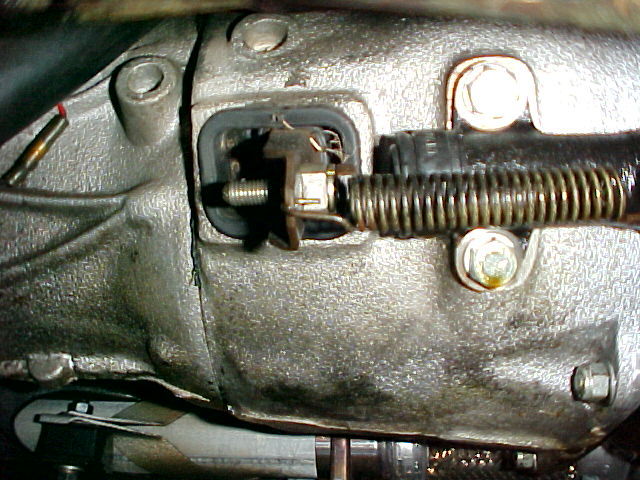

Incorrect adjustment at the slave. Jack the car up and place it on jack stands for safety. The clutch slave is located on the passenger side of the tranny. You will see a hose running from the clutch master cylinder to the slave. There is also a spring on the slave. Remove the spring to make your adjustments. You should notice a locking nut and an adjustment nut.

With a flat tip screw driver holding the adjustment rod back off the locking nut. Now tighten the adjusting nut so it takes the slack out of the clutch fork sticking out of the tranny. Back off one quarter turn and tighten up the locking nut. Put the spring back on and go for a spin. Hopefully you will enjoy the ride.

Worn components can cause you problems as well and it throws the geometry off. After 30 plus years of service things tend to wear out. Take a good look at the clutch master rod yoke and the clutch pedal where the clevis pin connects the two. All three parts could be suffering some sort of wear. This wear makes things not work properly. There are serveral solutions. Braze/weld the rod yoke/clutch pedal holes and redrill. Install a new clevis pin. Or--you can over drill the rod yoke and clutch pedal and install a bushing and a clevis pin to fit the bushing.

Things to check once the engine/tranny are pulled:

- Worn pilot bushing

- Worn pressure plate and/or disc

- Worn throw out bearing

- Incorrect installation of clutch disc

- Incorrect pilot bushing used

- Incorrect clutch package installed

- Incorrect assembly of fork/throw out bearing

- Incorrect throw out bearing

- Incorrect installation of clutch disc

Some general notes on the above. The pilot bushing may be in crooked, causing binding to the end of the transmission input shaft. The pilot bearing could be the incorrect size having an undersized hole in it. This would bind the tranny shaft. Worse case you could have a bent input shaft. With engine and tranny pulled as a unit from the car, put the trans in third gear for the 5 speed , or fourth gear for the 4 speed and try turning the transmission output shaft. There should be little friction, but no more than turning the trans without the engine attached. If you cannot turn it, or it is difficult to turn, the problem is with the shaft or bearing. If not, the problem is with the clutch disk or pressure plate. The disk could be warped, allowing the disk to hit the flywheel and pressure plate when the clutch is disengaged. Put the disk onto the trans input shaft and spin it. It should be flat and any wobbling indicates a problem. Take the pressure plate to a clutch rebuilder to have them check it out.

Another thing to check is the clearance between the input shaft and the crank, especially if you have had the flywheel surfaced or if you have replaced a 4 speed with a 5 speed. If there is no clearance then the shaft hits the crank. This not only causes the transmission to turn but will quickly wear out the thrust surface on the crank. That is a very bad thing. I almost found this out the hard way when I put a 5 speed behind my R16 stroker and used the R16/4 speed backing plate. The U20/5 speed backing plate is much thicker than the R16 so using the R plate with a 5 speed puts way too much pressure on the crank and its thrust bearing.

That pretty much covers the clutch system. Time to take a spin!