Published 2019 Updated 2022

R16 Timing Components and Cam-SAE vs. Metric

As a Go-No Go use a 10mm x 1.5 bolt to ensure you have a Metric cam.

This information was brought to light when I was building a stroker motor with David Premo. Dave and Stan had built a stroker motor years earlier and noticed the difference between the SAE and a Metric cam sprocket. This could also affect a standard motor build as well. The cam sprockets carried by MotorPower INC-the forklift folks is a metric cam sprocket. If you are building an early motor this sprocket is approximately 3 to 6 degrees off from the early SAE sprocket. That does not sound like much but when it comes to timing it is far too much. Your motor will not function properly and no matter what you do nothing will improve performance. JT says "That’s why it’s easy to think everything is fine when mixing up the gears. The timing marks line up OK with each other, but the cam is rotated 3 or 6 cam degrees. (6 or 12! crank degree)"

On my early three main stroker motor build I opted to go with a later metric cam, a new Japanese aftermarket cam sprocket and a new Japanese aftermarket timing chain. After looking over the sprocket and chain from MotorPower Inc. this was the correct path to take. The sprocket and chain were not quite up to Dave P's standards. He conversed with JT and JT agreed.

This peaked Curtis's attention as he had a motor that he was having issues with. In the end he did in fact have an early SAE motor with a metric cam sprocket.

JT commented on potential issues.

"Assuming a stock cam and no valve/piston collisions, just about any poor running situation you can think of because ALL the valve events are out of sync with the crank and pistons.

At a minimum, it will never feel "right" or want to rev well. If you measure it with a dyno, you'll be well off the factory torque curve at most if not all rpms. Sluggish and mis-tuned.

The exact symptoms depend on what parts were swapped and whether the cam is badly advanced or retarded. If advanced it may idle fine, but be struggling at rpm. If too far retarded will have lousy low end, poor mid range and still under-powered in the top end.

Depending on CR and cam grind it may behave like the ignition timing is too retarded and may also run hot. Lots of possibilities, but lots of variables too, so a myriad of effects. In short nothing good."

More from JT.

“As original” early timing gears. Note the timing marks are offset from the teeth in this version, Problem is some metric gears are marked in a similar fashion, so you can really tripped up if you go with visual comparison- the timing marks are just tooth markers and not particularly precise-can be many degrees off.

The method Curtis showed at the top is a decent way to verify- if you have a cam sprocket 1/3 tooth “off” from a late metric sprocket with the key ways aligned, it is an early sprocket.

Another possible way to ID cam sprocket is by keyway, the early sprocket slot is 5/32 which is .001 under 4mm. Thus 4mm keystock is a tight/interference fit. 4mm keystock slips right in the metric sprockets. (This test assumes accurate gears, accurate keystock etc.).

This is also why a metric sprocket will slip right on the early cam which causes big problems.

Also the cam bolt is different from the two cams. 3/8-16. (3/8 NC , 3/8 USS) for the early cam. 10m x 1.5 for metric.

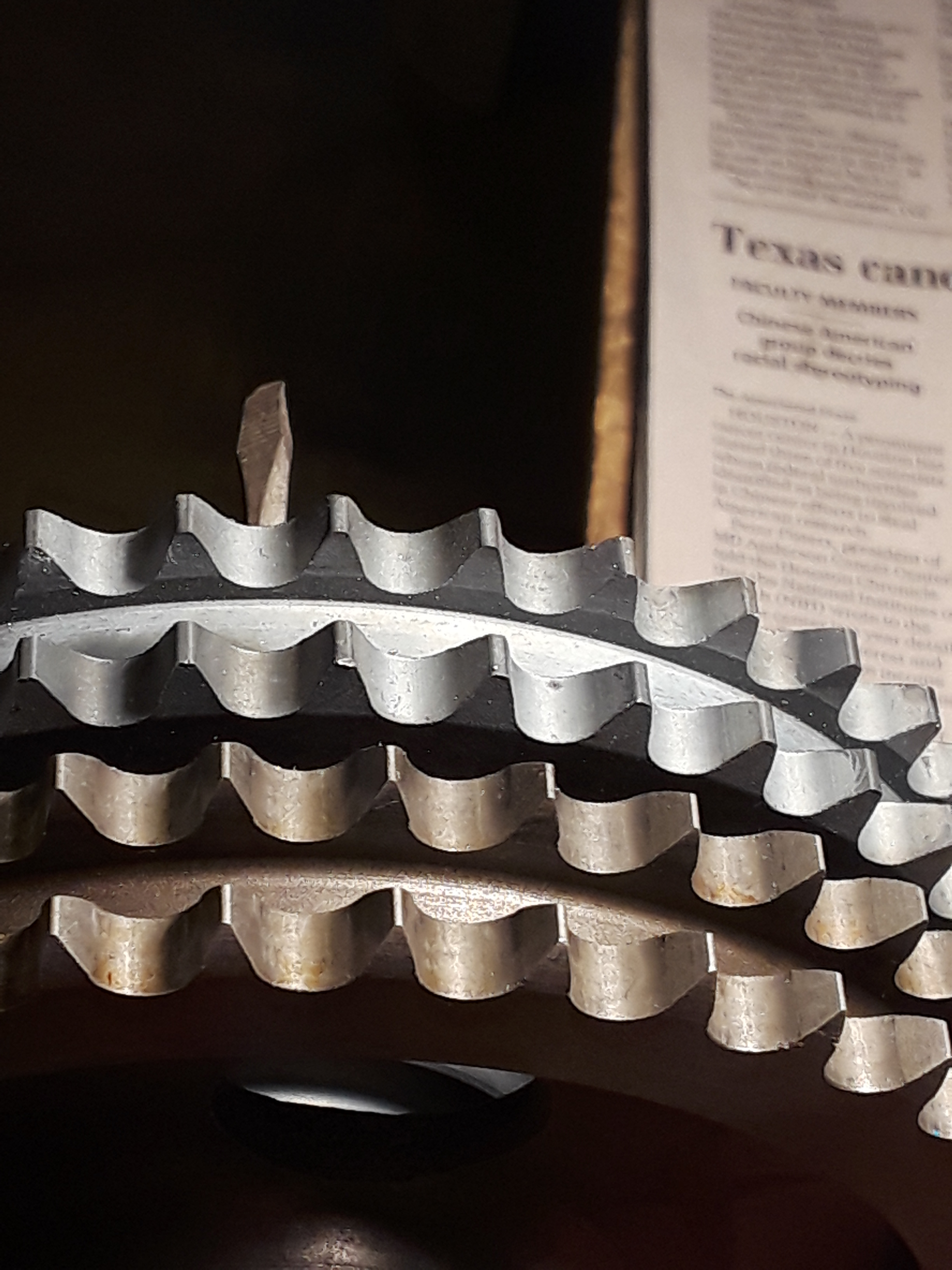

Here are a couple of pictures showing the differences between the SAE and Metric sprocket.

Thanks go to Stan, Dave, JT and Curtis for bringing it up in the first place and discussing this further. Hopefully this will save someone from building an under performing motor.