Interior aluminum trim restoration

by guyatou

I get a lot of help and advice from everybody on here, but I rarely have any good tech advice to contribute to the group. However, I am picky about bright work, and know a bit about how to make our cars shine. (I had my own aircraft detail company when I was in high school.)

I decided to tackle my very bad ribbed aluminum kick panels and door sills this week. It took some work, but yielded nice results.

Step 1: Remove panels, degrease if necessary. Clearly mine have seen better days.

Step 2: Scrub with a brass brush and water. (DO NOT use steel wool or a steel brush. They are too harsh.) You can be somewhat aggressive with this step, but make sure to keep the surface wet, and wipe away the black debris as you go. Brush in line with the ribs of the metal. This step removes big debris, and will remove some of the coarse defects. Work in small patches.

Step 3: The metal is clean but very dull because you've completely scuffed up the original factory polish. Don't panic! Rise with water.

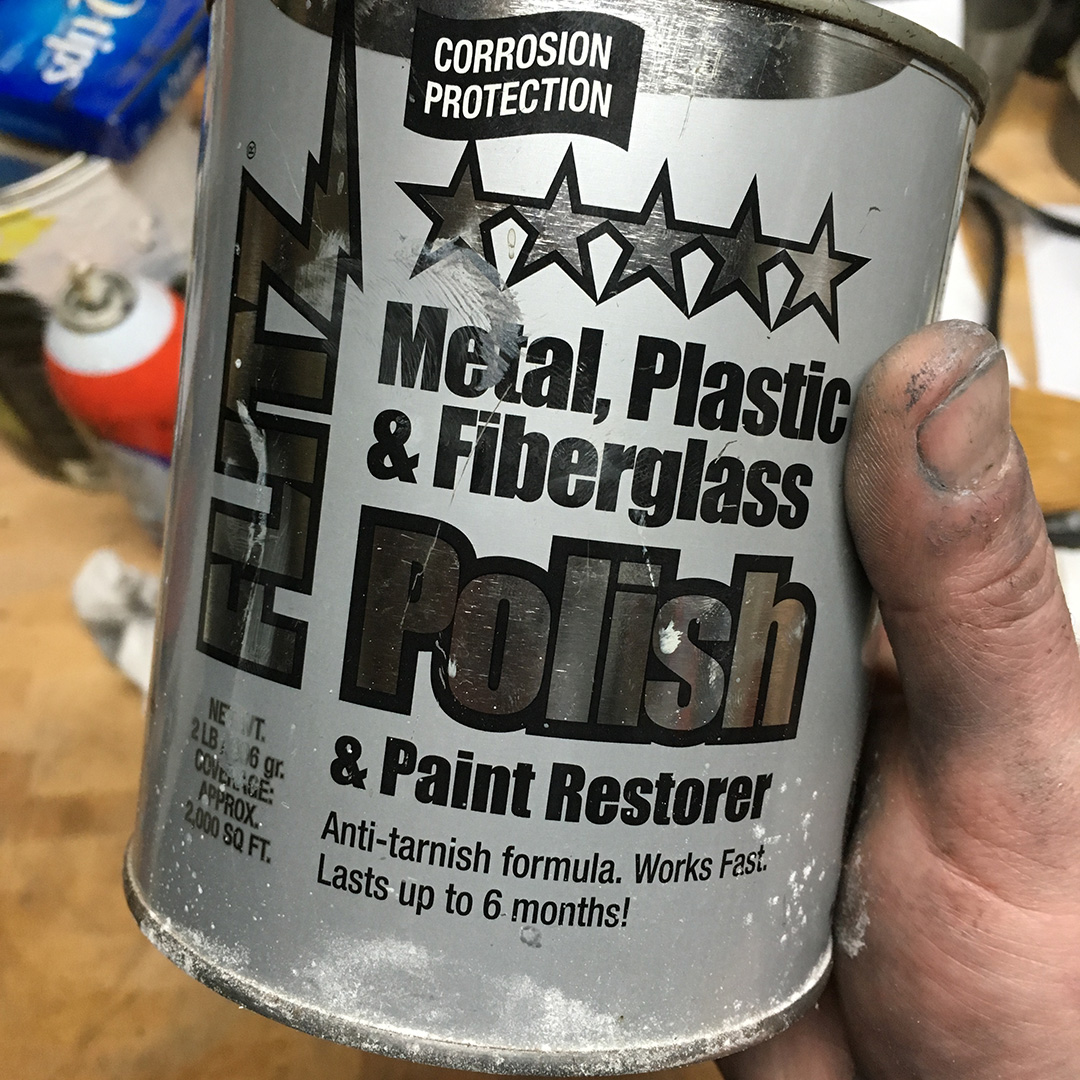

Step 4: I use a metal polish called Flitz that we used the 90s at the airport where I worked. It's safe for chrome, aluminum, plastic headlights, etc. I used to polish aircraft windscreens with it -- and silver flatware. It's somewhat hard to find these days. I think I got this can from Amazon some years ago. Any metal polish will probably work, but this is what I use for everything. My recollection is it's made with aluminum oxide, so it's not very aggressive, unlike some polishes.

Step 5: Using a terrycloth rag, apply polish and rub in the direction of the ribs of the metal. A heavy terrycloth works better than a smooth shop rag due to the ribs. Work in small areas and wipe with a clean cloth on occasion to see your progress. You can't overdo this step in my experience, so keep at it until it looks pretty good. Wipe down with a clean section of your cloth again when you're pleased with the results.

Step 6: Extra credit: Polish with a stiff toothbrush to get down in the grooves a little farther. Wipe with a clean section of cloth. The toothbrush stage may be overkill, but I want this to shine like a diamond in the sky. And I'm a little OCD about these things. Wipe with a clean section of cloth. You'll notice the metal looks pretty good, but it's a little hazy and dull. Onto the next step!

Step 7: Time to pull out the secret weapon: Raid the cupboard for some regular old flour. Sprinkle the flour on the metal. You don't have to go full-on Tony Montana here, a little white powder will go a long way. :D Grab a fresh terry towel and polish the metal with the flour. Don't reuse your previous towel for this step. A lot of black oxidation will come off on the rag. The aluminum will quickly look good -- don't spend a lot of time on this step. (If it isn't shiny enough for your taste, go back to either Step 5 or Step 6.)

Step 8: Admire your fine handiwork and reinstall.

I hope this helps someone get their car shined up. My 68 SRL has terrible paint (3 layers!) and some major dents, but I get compliments on it all the time -- mostly because the bright work is always shiny and attracts the eye away from its defects.

You might check with an expert before you get this aggressive with a Concours-level car -- this process dulls and replaces the factory polish completely on the aluminum parts (the brass brush step) and that may be a no-no for high-end cars. But for your average driver, this will make your bright work pop! Failing the brass brush, you can just use more elbow grease and stick with metal polish only. I've tried that in the past, but for these solid aluminum parts, it takes forever to get a good shine.

NOTE: If you decide to clean up your chrome bright work DON'T use the brass brush. Flitz or other metal polish with some elbow grease will be sufficient and safe for the metal.