Page 1 of 1

1600 Head Rebuild

Posted: Sat Oct 17, 2015 8:40 pm

by Andy_In_SD

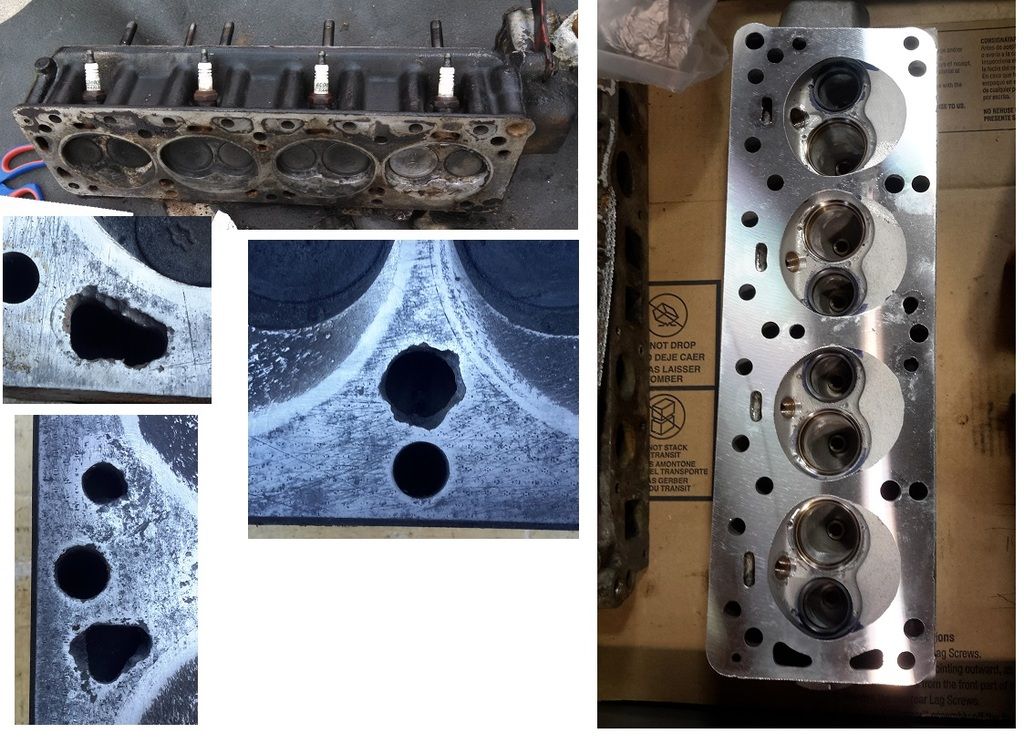

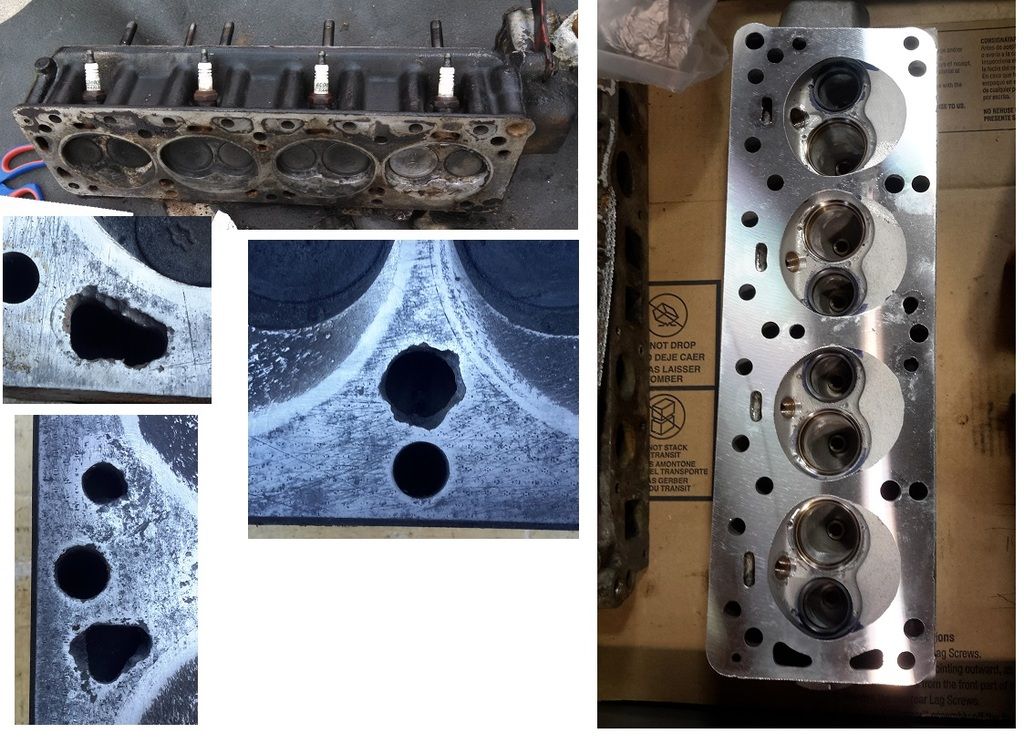

Besides my 70, my daughter has a 66 1600. The head was in pathetic shape so we sourced a replacement and sent it off to a machine shop for a rebuild. You can see the rot on the water gallery holes, too close to combustion! And how deep does that rotten aluminum rabbit hole go?

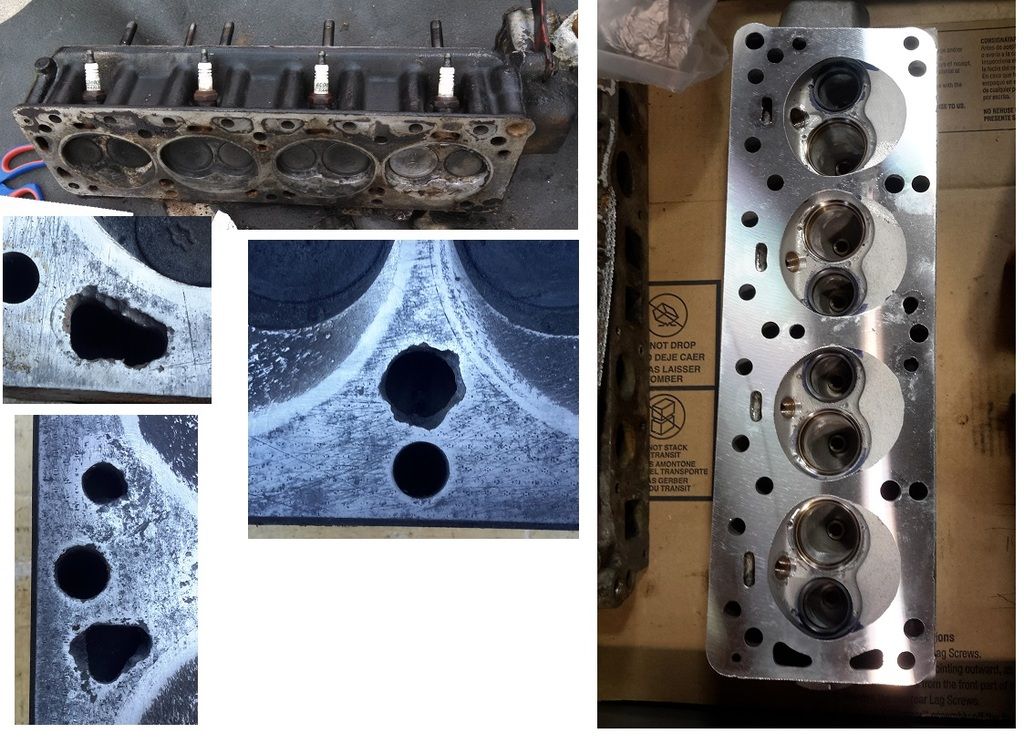

So, all of that was welded up. Head skimmed, new valves, plug holes sleeved etc... etc.... Here is the before and after. This should go onto the block next weekend.

Re: 1600 Head Rebuild

Posted: Sun Oct 18, 2015 8:50 am

by S Allen

The head looks great. Amazing what a good machine shop can accomplish.

Steve

Re: 1600 Head Rebuild

Posted: Sun Oct 18, 2015 12:07 pm

by Curtis

I'm a bit confused. You mention aluminum but the head looks cast iron. Which is it and if it is cast iron then welding it is of course a tricky thing.

Re: 1600 Head Rebuild

Posted: Sun Oct 18, 2015 4:51 pm

by Andy_In_SD

It is aluminum (an A-12 head). It looks cast due to abuse (if you look at someone trying to perhaps wire wheel it, or sand with 80 grit. You can see the gouges and scrape marks on it) and the crud. I've never had a cast head for an R series block, hopefully you have (or have knowledge on them), are they better? ie : less chance of the "bends".

As a bit of trivia, the A-12 head is also used in old Nissan forklifts so you can source valves, stems etc... that way as well, easier & cheaper. As an aside, as it is an A-12 head it is 100% compatible with an R-series. The only difference is in the valve shims. The A-12 has a "stair step" for the inner & outer springs and each takes it's own shim. It does not take the valve shims you see for sale for R-Series on the usual sites (with the "hat" look").