For those considering this swap and would like to use our

SR20 Conversion Parts, I would highly recommend renting our JIG to place the motor mounts in the correct location on your frame.

This is "Jiggy":

What Jiggy does is hang two motor mount base plates in space allowing you to trim the motor mount base plates that come with our kit to match your frame. Due to the many minor variations that we have seen in the frames over the years, we have found this to be the best method to get the best fit for individual frames.

After looking at dozens of frames, we have found that the spacing for the body mounts in the engine compartment have been pretty universal and we designed two 9/16" pins that fit into these holes (the roadster holes are about a 1/32 undersized, so we drill them out with a 9/16" drill bit to make a nice secure fit!):

When both holes are drilled out, the pins slide into the holes, and a simple C clamp is used to keep the jig sitting secure and square:

Neither motor mount base plate on the JIG actually touches the frame at this point:

The motor mount base plates that I send out with my kits need to be trimmed to match the profile of the frame (you can see about 1/4"-3/8" of excess material that will need to be trimmed:

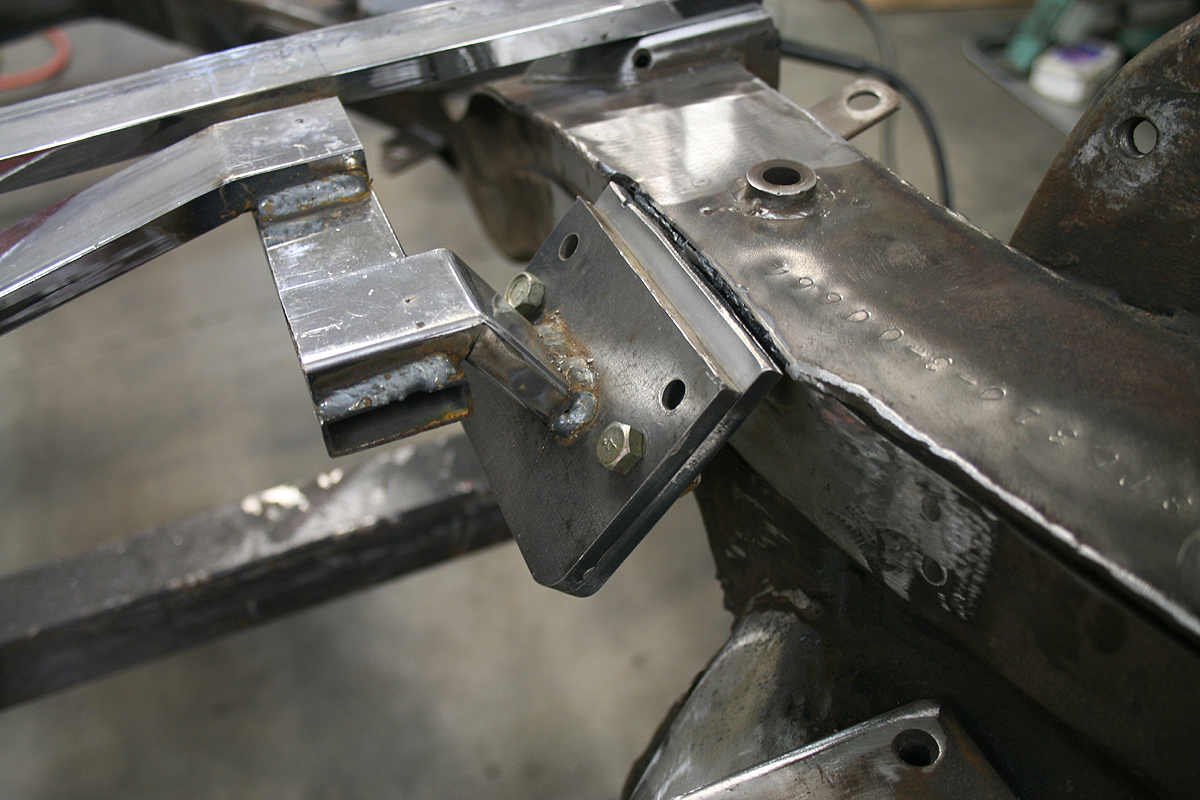

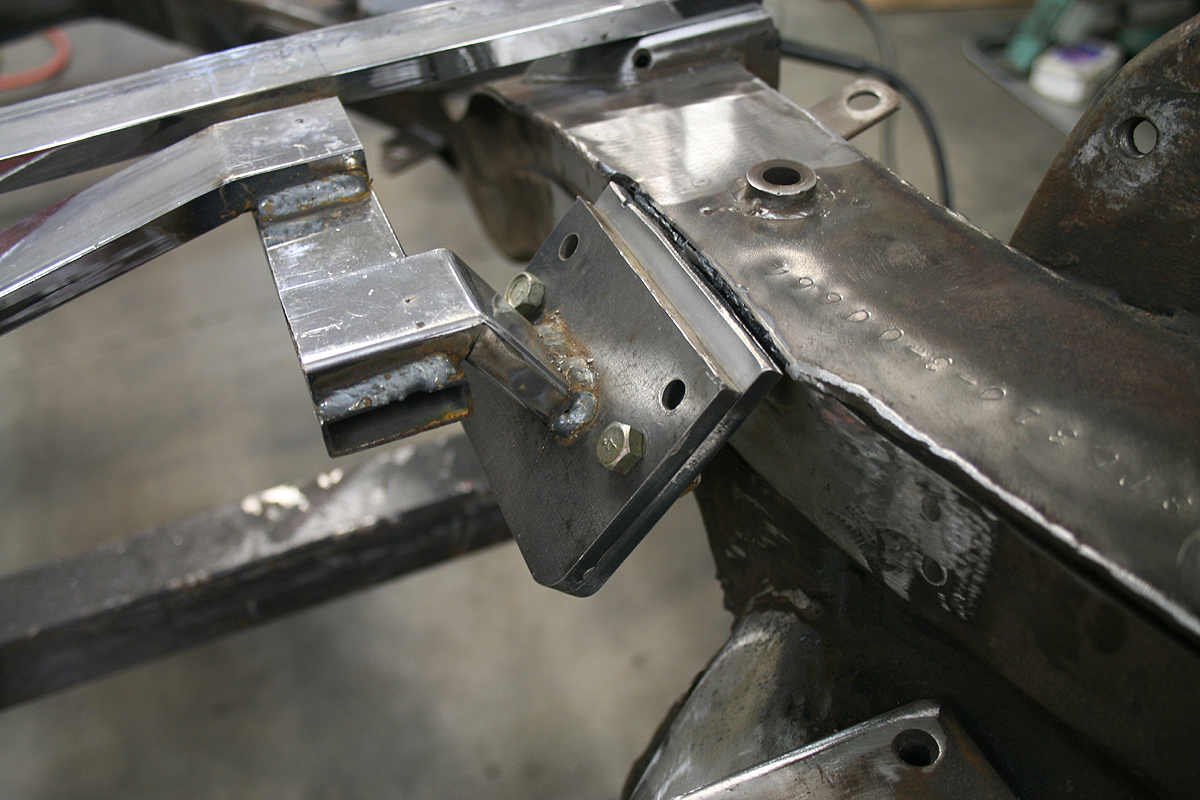

After trimming back the overlapping top piece, we actually get to the frame sidewall. The trimmed motor mount base plate is bolted to the JIG using the provided 8mm bolts:

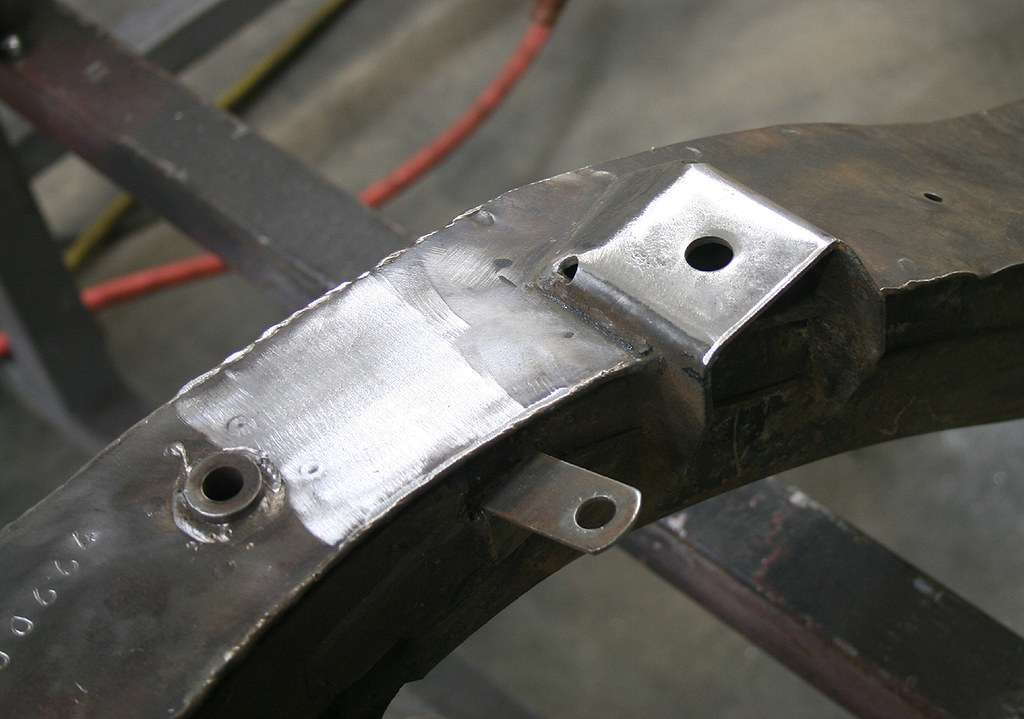

The motor mount base plate is welded in two passes, first a root pass to get things seated to the vertical portion of the frame rail, then a wider top pass to tie the gap together (be careful not to get your weld into the chassis VIN number-- a 1500 VIN is longer so it gets closer to the edge of the frame rail):

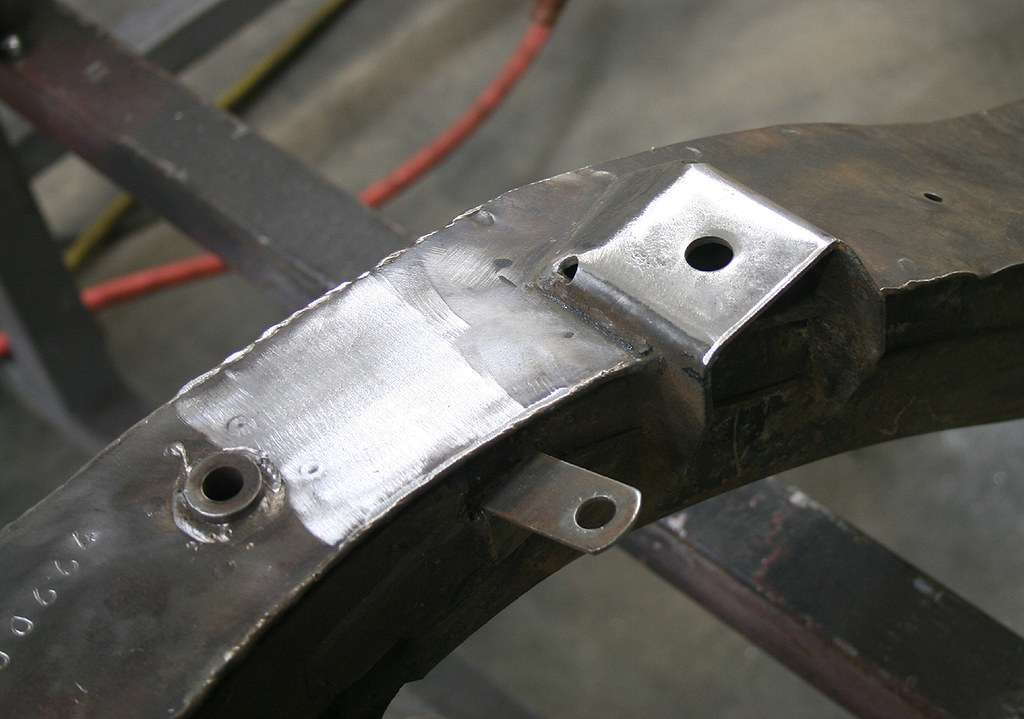

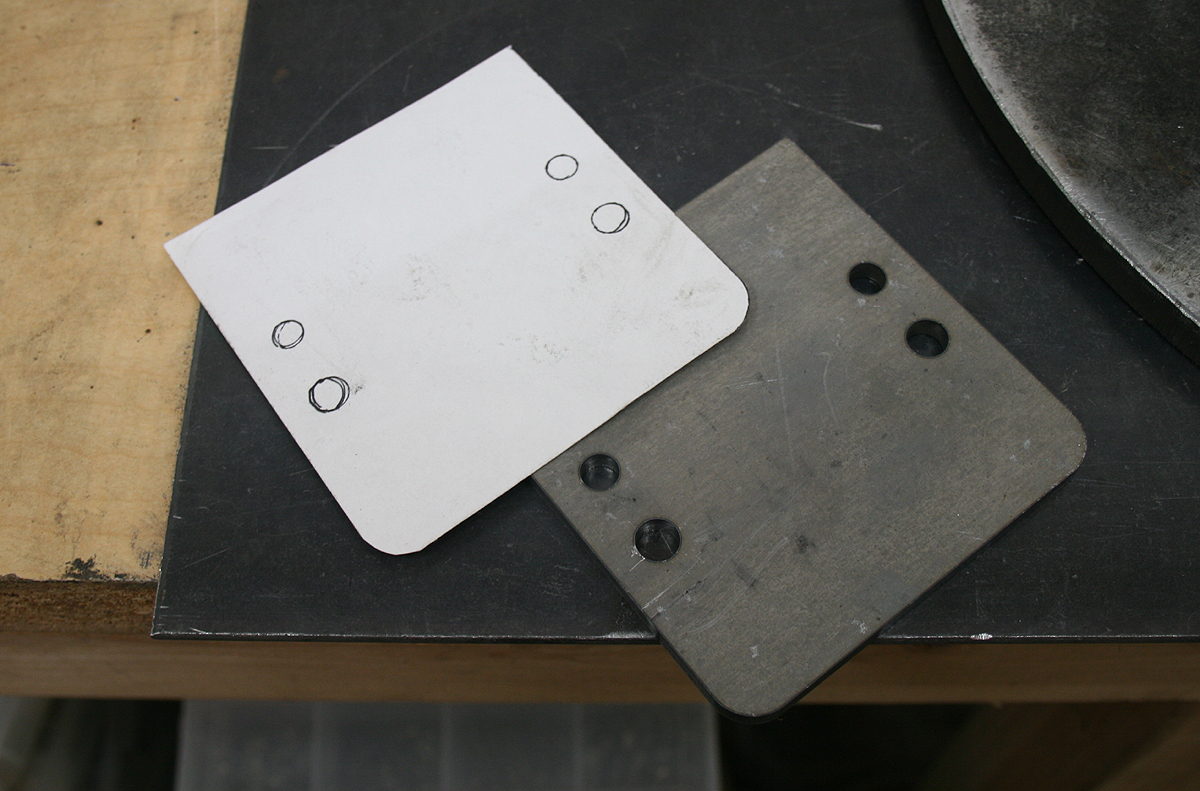

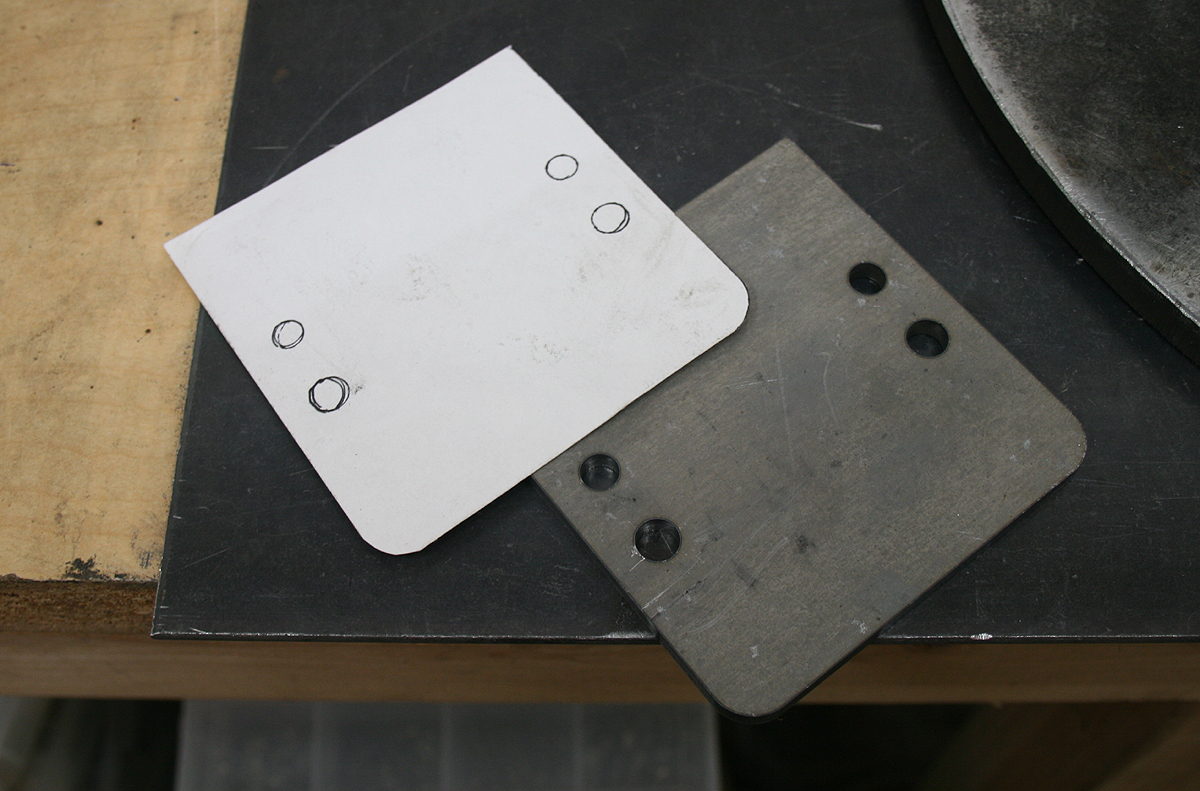

The passenger side is a little different. Where the motor mount plate is located the frame actually curves away and has a step in it, so the cut on this is a little more difficult to figure out. I like to make a pattern on card stock so I can figure out the cuts on the base plate:

Then it is just a matter of trimming and lining up the holes to make sure that there is a good fit on the passenger side frame rail:

Trim, adjust, weld, grind... you know the drill!

That takes care of the motor mount base plates, then it is just a matter of building some new side gussets to tie them into the frame:

If you are considering a SR20 swap into your roadster, Jiggy makes things much easier as it takes all the guess work out of the project, and will easily save you 8-10 hours of setup time. Contact me directly for rental information! Jiggy has been sent all around the country (even Alaska and Canada!) and feedback has been very positive!