With the majority of the driver's rocker cut off the car, this morning was spent cutting out the remains so the newly rebuilt donor rocker panel could be installed. Since both the A-pillar and the rear quarter panel overlap the rocker panel, it took quite a bit of time to cut out the remains so the new panel could be slipped into place.

The first part that needed to be dealt with was the bottom of the A-pillar. When I cut the old panel out, I just trimmed around the existing welds, and the plan was to die grind the material away. But after seeing what the inside of the rocker panel looked like, plus with my experience with the bottom of the passenger A-pillar, I decided to cut the bottom portion of the A-pillar out-- and in hindsight, I am glad I did, it was full of crud:

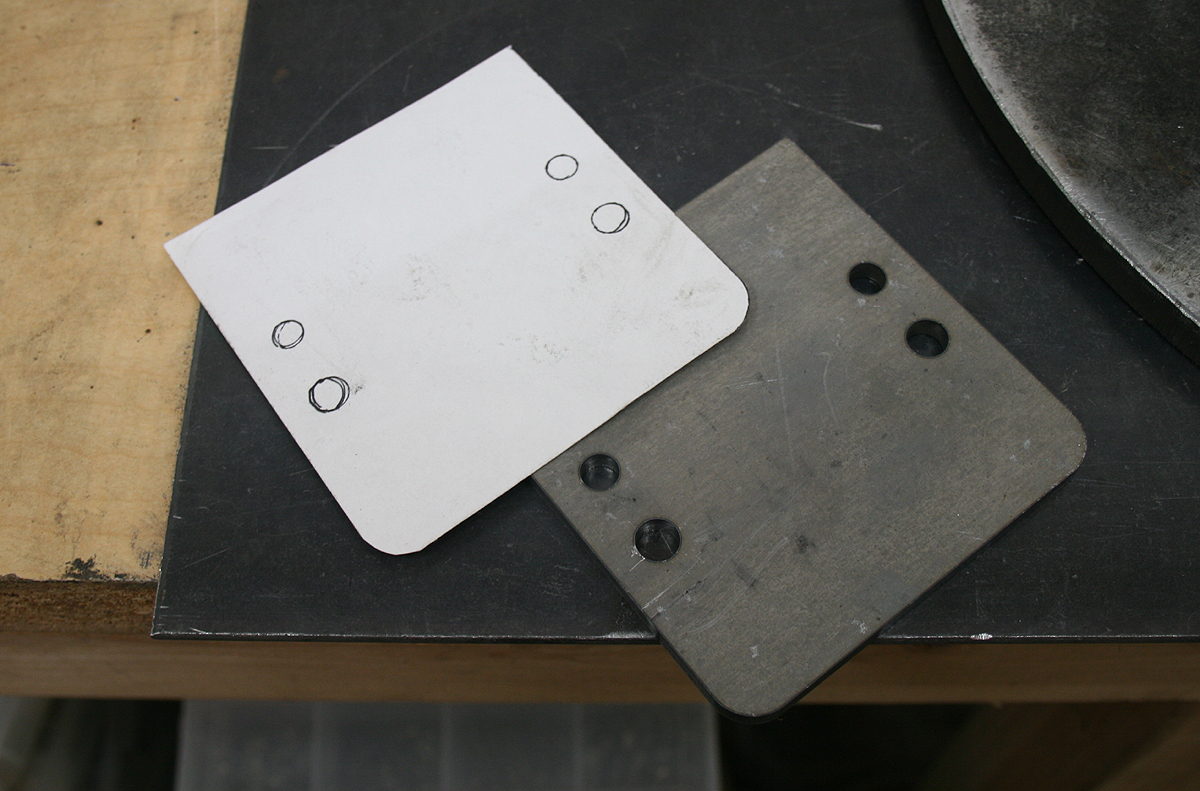

Since the kick panel in front of the A-pillar also overlaps the rocker panel, it needed to be carefully spot weld drilled so I could remove the section that is sandwiched between the rocker panel backing plate and the kick panel:

With all of that removed, all the sections were wire wheeled and prepped for the new rocker panel.

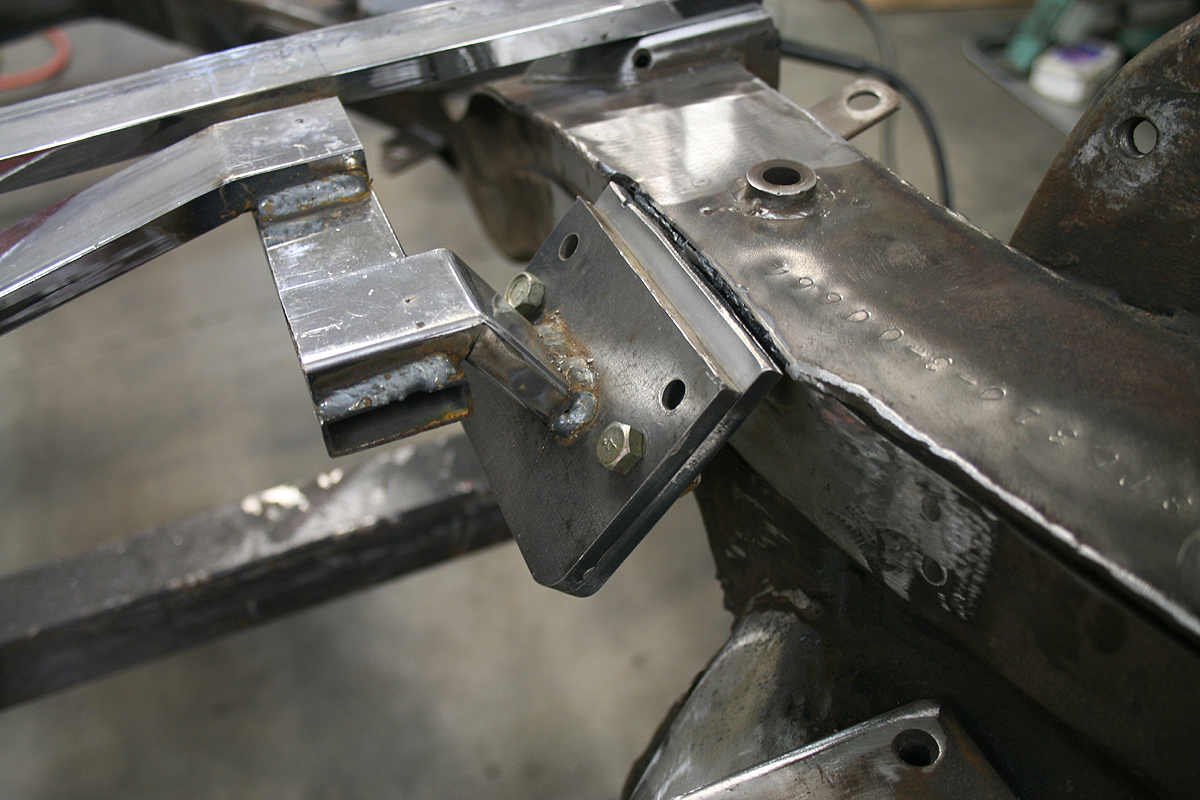

The rear portion of the rocker panel is also overlapped by the quarter panel. Since I did not want to cut any more of the rocker panel out than I had to, I had to figure out a way to get access to the top portion of the rocker panel where it is welded to the backing plate. The only way to do this was to cut an access hole in the inside quarter panel backing plate:

This allowed me to get the plasma cutter in so I could cut out the remains of the original rocker panel:

Then from the bottom side, it was just a matter of using my die grinder with a carbide bit to cut out the remains:

Now I could get inside the quarter panel with my wire wheel and clean and paint it before the new rocker panel was installed.

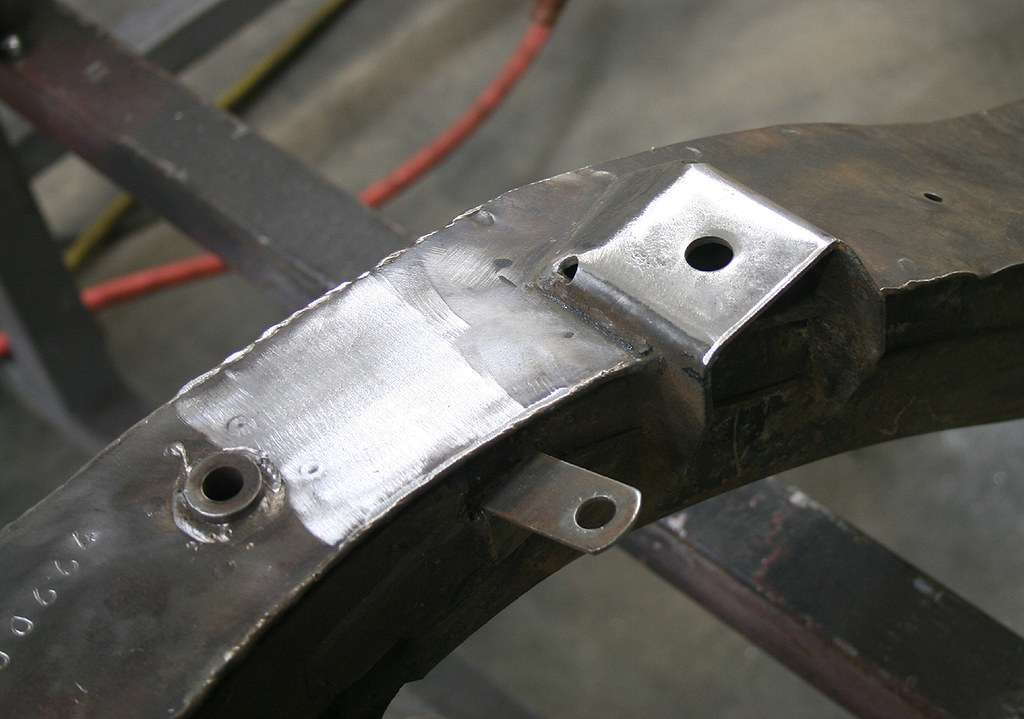

As I mentioned earlier, a 'new' rocker panel was sourced, but even that needed to have the front and rear sections rebuilt due to rust damage... After that was completed, the entire backside was cleaned, and painted with Zero Rust:

The end that is overlapped by the quarter panel was also painted with Zero Rust as I won't be able to paint it once it is installed:

The rocker panel backing plate was also cleaned up, the jack point hole was welded up (they will be removed from this car), and the panel was masked, and painted with Zero Rust:

Guy Byrd was here helping again today, and with all the grunt work out of the way, I turned him loose with the rocker panel so he could make sure that all the gaps are correct and everything is sitting like it should. He reinstalled the driver's door, and adjusted everything until the gaps were all correct. Then it was just a matter of welding it into place.

And as it sits tonight (still need to finish grind everything, but you get the idea):

Tomorrow we will finish the front half of the quarter panel and I will rebuild the front leg of the A-pillar...

Happy New Year everyone!

Michael